Clean new energy, such as photovoltaic and wind power, is being sought after globally because of its low cost and green. In the process of PV power station components, special PV cables are required to connect PV components. After years of development, the domestic photovoltaic power station market has successfully accounted for more than 40% of the world's photovoltaic power generation. So what types of PV lines are commonly used? Xiaobian carefully sorted out the current PV cable standards and common models around the world.

First, the European market needs to pass TUV certification. Its model is pv1-f. the specification of this kind of cable is generally between 1.5 and 35 mm2. In addition, the upgraded version of h1z2z2 model can provide stronger electrical performance. Secondly, the American market needs to pass UL certification. The full English name of this certification is ulcable. The specifications of photovoltaic cables passing UL certification are usually within the range of 18-2awg.

The purpose is to transmit current. The difference is that the requirements for the use environment are different when transmitting current, so the materials and processes that make up the cable are different.

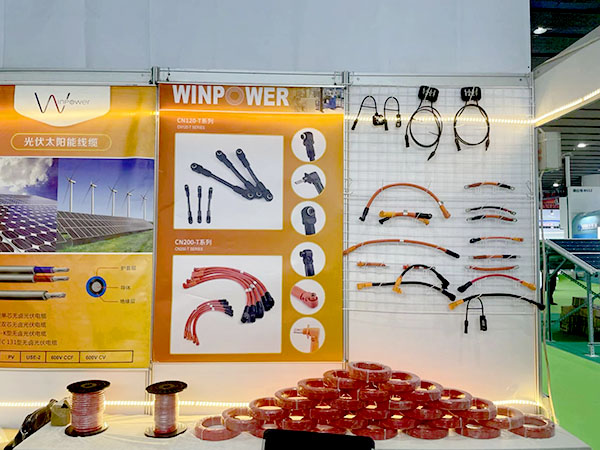

Common photovoltaic cable models: PV1-F, H1Z2Z2-K, 62930IEC131, etc.

Common common cable models: RV, BV, BVR, YJV, VV and other single core cables.

Differences in use requirements:

1. Different rated voltages

PV cable: 600/100V or 1000/1500V of the new standard.

Ordinary cable: 300/500V or 450/750V or 600/1000V (YJV/VV series).

2. Different adaptability to the environment

Photovoltaic cable: It is required to be resistant to high temperature, cold, oil, acid, alkali, rain, ultraviolet, flame retardant and environmental protection. It can be used in harsh climate with a service life of more than 25 years.

Ordinary cable: generally used for indoor laying, underground pipe laying and electrical equipment connection, it has certain temperature and oil resistance, but can not be exposed outdoors or in harsh environments. Its service life is generally based on the actual situation, without special requirements.

Differences between raw materials and processing technology

1. Different raw materials

PV cable:

Conductor: tinned copper wire conductor.

Insulation: cross-linked polyolefin insulation.

Jacket: cross-linked polyolefin insulation.

Common cable:

Conductor: copper conductor.

Insulation: PVC or polyethylene insulation.

Sheath: PVC sheath.

2. Different processing technologies

Photovoltaic cable: the outer skin has been cross-linked and irradiated.

Ordinary cables: generally do not undergo cross-linking radiation, and YJV YJY series power cables will be cross-linked.

3. Different certifications

PV cables generally require TUV certification, while ordinary cables generally require CCC certification or only a production license.

Post time: Nov-21-2022