I. AGC – Automatic Generation Control

1. Overview of the AGC System

Core Objective: Maintain stable grid frequency and balance active power supply and demand across the grid.

Control Target: Active power output from power plants.

The grid dispatch center’s energy management system calculates total active power adjustment needed for frequency stability. It bases this on system-wide load forecasts, unit status, line schedules, and real-time frequency. The system allocates this demand to each power plant, including PV stations, using specific strategies such as proportional regulation. The dispatch center sends real-time setpoint commands to the PV AGC system through dedicated communication channels like the Power Dispatch Data Network. When the PV AGC receives a command, it quickly adjusts active power output to match the setpoint.

2. How do PV power plants achieve AGC regulation?

Active Power Limitation: The most common method. When the setpoint is below the current maximum achievable power output, the AGC system controls the inverter array to reduce actual output power (“load shedding”).

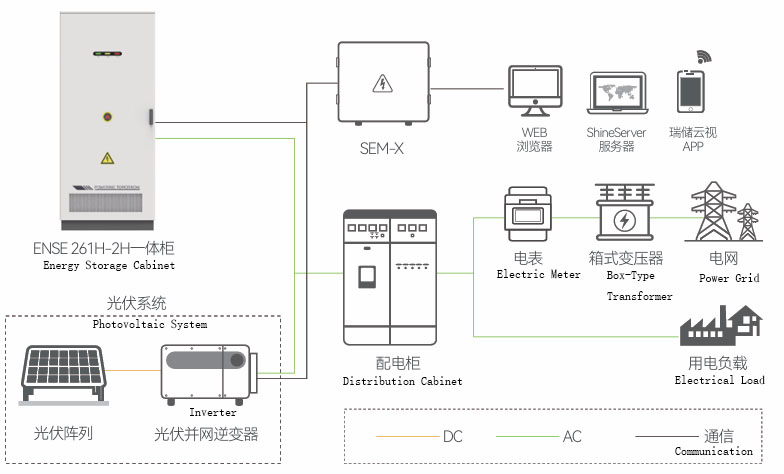

If the plant has a battery energy storage system, AGC can command it to charge or discharge. Charging absorbs active power, which reduces plant output. Discharging increases active power output. This makes PV plants more flexible and improves their ability to join AGC regulation, especially when more output is needed.

Power Curtailment: When the setpoint requires output below the maximum power achievable under current sunlight conditions, this essentially constitutes active power curtailment.

3. Why must PV power plants participate in AGC?

Grid frequency is a key part of power quality. Load fluctuations cause frequency to change from the rated value. Traditional plants respond through governors. However, with more renewables, PV plants must also help regulate frequency.

Meeting Grid Connection Requirements: Modern grid regulations mandate that large-scale PV plants possess AGC capability and can adjust active power output according to dispatch instructions.

Participating in Power Markets: Providing AGC regulation capacity in ancillary service markets generates revenue.

II. AVC – Automatic Voltage Control

1. AVC System Overview

Maintain grid voltage within safe ranges, optimize reactive power, and reduce transmission losses.

Control Target: Reactive power output from the power plant (or target grid connection point voltage).

The EMS at the grid dispatch center calculates total reactive power adjustment or voltage targets needed for voltage stability. It distributes these to AVC power plants and substations, including PV stations. The dispatch center sends setpoints or voltage commands to the PV AVC through communication channels. On receiving the command, the PV AVC adjusts reactive power output or controls voltage at the connection point.

2. How do PV power plants achieve AVC regulation?

PV inverters can operate in all four quadrants and can generate or absorb reactive power while making active power. The AVC system guides all inverters so the plant meets its reactive power or voltage goals.

SVG/SVC: If the plant incorporates dedicated static var compensators (SVG: Static Var Generator, SVC: Static Var Compensator—devices for reactive power regulation), the AVC system also controls these devices to generate or absorb reactive power.

If the plant’s main transformers have on-load tap-changing ability, AVC can also control these. This helps manage internal voltage and coordinate reactive power output.

3. Why do PV power plants need to participate in AVC?

Too much or too little reactive power is the main reason for grid voltage swings or collapse. PV plants usually connect at grid endpoints, so their output changes—especially at sunrise, sunset, or during clouds—affect local voltage. Joining AVC helps PV plants support voltage stability.

Grid connection standards require PV plants to have AVC features. These include a specific range for reactive power adjustment, a fast response time, and the ability to receive dispatch orders.

Reducing Grid Losses: Proper local reactive power compensation and voltage control help optimize reactive power flows within the grid, thereby reducing transmission losses.

Good voltage support boosts the grid’s ability to handle faults.

III. Key Differences and Connections Between AGC and AVC

| Characteristics | AGC | AVC |

| Core Objectives | Maintain grid frequency stability (active power balance) | Maintain grid node voltage stability (reactive power balance) |

| Control Variables | Active Power | Reactive Power (or grid connection point voltage) |

| Regulation Methods | Limit active power output, energy storage charging/discharging, curtailing solar generation | Inverter reactive power generation/absorption, SVG/SVC, transformer tap changer |

| Response Targets | System frequency deviation, dispatch active power setpoint | Node voltage deviation, dispatch reactive power/voltage setpoints |

| Grid Support | Primary frequency regulation (optional), secondary frequency regulation (primary) | Static/dynamic voltage support |

| Contact | Both work in tandem to ensure the secure, stable, and high-quality operation of the power grid. Significant fluctuations in active power may also affect voltage, while reactive power regulation can slightly impact active power output (inverter capacity constraints). Dispatch instructions require coordination. | |

Summary:

(1) AGC acts as the “active power remote controller” for PV plants, adjusting generation levels under dispatch commands to stabilize grid frequency.

(2) AVC functions as the “reactive power/voltage remote controller,” regulating reactive power output (or directly controlling grid-connection point voltage) to stabilize grid voltage.

Both AGC and AVC are key controls at large modern PV plants. They are necessary for PV plants to join the grid as friendly power sources, help regulate the grid, and comply with connection rules. AGC and AVC help turn PV plants from simple generators into active supporters of grid stability.

PV output is intermittent and fluctuating, making AGC and AVC tracking difficult. Frequent deep regulation may shorten equipment life. High communication speed and reliability are also critical. Adding energy storage can improve AGC and AVC in PV plants.

Winpower Cable is a provider of connection solutions for the new energy system.

Our main products: Solar PV Cable, Energy Storage Cable, EV Charging Cable, Solar PV Cable Harness, Energy Storage Cable Harnesses, and Automotive Cable.

Winpower Cable has passed UL, TUV, VDE, CE, CSA,CQC Certification.

Our main markets: United States, Europe, Middle East, Southeast Asia. And we have 13 years of export experience.

Post time: Sep-23-2025