In the fast-growing new energy industry, cable conductor materials play a decisive role in determining the efficiency, safety, and lifespan of power systems. Whether used in solar photovoltaic (PV) cables, electric vehicle (EV) charging lines, or energy storage harnesses, the choice of conductor—copper, aluminum, copper-clad aluminum (TCCA), tinned copper, or copper alloy—directly affects performance and cost. Each material offers unique properties in terms of conductivity, weight, corrosion resistance, and mechanical strength. Understanding these differences is essential for engineers, manufacturers, and buyers seeking the best balance between power efficiency and economic value.

This article provides a detailed comparison of the most common conductor types used in new energy cables, covering their composition, resistivity, density, appearance, and application suitability. By the end, you’ll have a clear guide to selecting the right conductor for solar, EV, or energy storage systems.

1. Introduction

With the rapid growth of renewable energy technologies such as solar power, electric vehicles (EVs), and energy storage systems, new energy cables have become essential components in sustainable power networks. These cables carry current efficiently and safely between modules, batteries, inverters, and control systems.

One of the most critical factors affecting a cable’s performance is its conductor material. The conductor determines the electrical, thermal, and mechanical properties of the cable, influencing everything from efficiency to cost.

In this article, we will compare the most commonly used conductor types in new energy cables — including copper, aluminum, tinned copper-clad aluminum (TCCA), tinned copper, and copper alloys — analyzing their composition, appearance, density, performance, advantages, and applications.

2. Common Conductor Materials in New Energy Cables

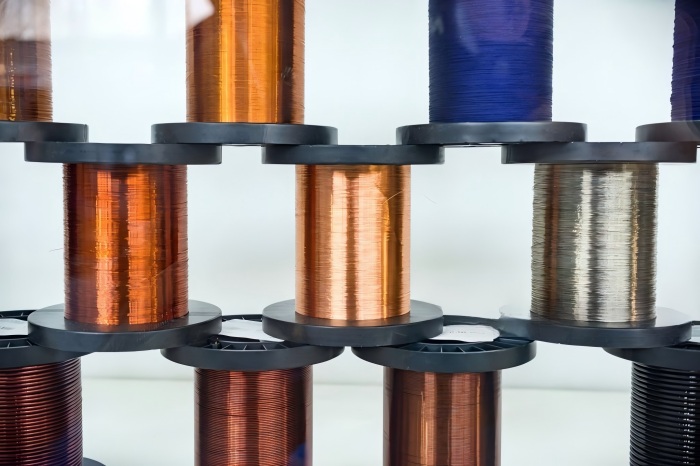

2.1 Copper (Cu)

Material Name: Copper

Elemental Composition: Pure copper (Cu ≥ 99.9%)

Abbreviation / Code: Cu, T2, or C1100

Appearance: Reddish metallic luster

Density: ~8.96 g/cm³

Copper is the most widely used conductor in new energy cables due to its excellent electrical and mechanical properties. With a very low resistivity of 0.0172 Ω·mm²/m, copper ensures minimal energy loss during power transmission.

It also has high tensile strength (200–250 MPa) and outstanding ductility, allowing cables to be easily bent and routed. Copper’s chemical stability is exceptional, resisting oxidation and corrosion under most conditions.

Advantages:

-

Best electrical conductivity among commercial metals

-

High flexibility and mechanical strength

-

Stable under high and low temperature variations

Disadvantages:

-

Heavier weight increases total cable mass

-

Higher cost compared to aluminum or CCA

Typical Applications:

-

Solar PV cables

-

EV charging cables

-

Energy storage cables

-

Grounding and battery connection wires

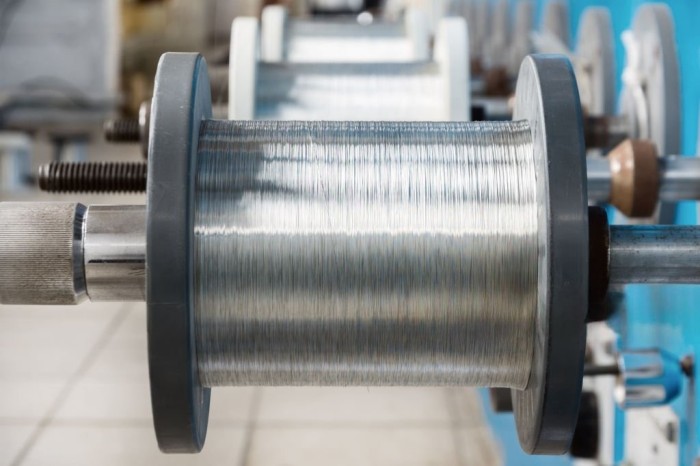

2.2 Aluminum (Al)

Material Name: Aluminum

Elemental Composition: Pure aluminum (Al ≥ 99.5%)

Abbreviation / Code: Al, 1350-O, or 8000 series

Appearance: Silvery white metallic finish

Density: ~2.70 g/cm³

Aluminum is an alternative conductor commonly used in large-scale power cables and cost-sensitive new energy systems. Its main advantage is its lightweight nature—about one-third the density of copper—making it ideal for applications where reduced weight is important.

However, aluminum has a higher resistivity (0.0282 Ω·mm²/m), leading to greater voltage drop and heat generation. It also has lower mechanical strength and flexibility compared to copper.

Fortunately, modern aluminum alloys and surface treatments have improved its durability and corrosion resistance by forming a protective oxide layer.

Advantages:

-

Lightweight and cost-efficient

-

Good corrosion resistance

-

Suitable for long-distance transmission

Disadvantages:

-

Higher resistance than copper

-

Less flexibility and lower strength

-

Risk of galvanic corrosion when connected with copper

Typical Applications:

-

Overhead transmission lines

-

Large cross-section power cables

-

Energy storage and utility-scale solar projects

2.3 Tinned Copper-Clad Aluminum (TCCA)

Material Name: Tinned Copper-Clad Aluminum

Elemental Composition: Aluminum core coated with 10–15% copper

Abbreviation / Code: TCCA

Appearance: Tinned Copper-colored surface, lighter than pure copper

Density: ~3.6–4.0 g/cm³

TCCA combines the benefits of both copper and aluminum. It has a lightweight aluminum core that provides structural strength, while the thin outer copper layer ensures good conductivity and corrosion protection.

Its resistivity (~0.026–0.028 Ω·mm²/m) lies between that of aluminum and copper, making it a good cost-performance compromise for many new energy applications.

Advantages:

-

Light weight reduces total cable mass

-

Lower cost than pure copper

-

Good balance between conductivity and strength

Disadvantages:

-

Higher resistance than copper

-

Not suitable for continuous high-current loads

Typical Applications:

-

EV charging cables

-

Energy storage harnesses

-

Data and communication cables

-

Cost-controlled solar installations

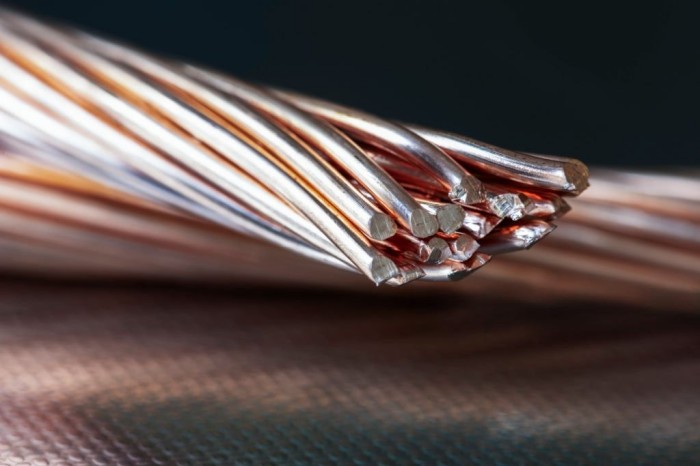

2.4 Tinned Copper

Material Name: Tinned Copper (Sn-coated Cu)

Elemental Composition: Copper coated with a thin layer of tin (Sn)

Abbreviation / Code: TC or Sn-Cu

Appearance: Silvery surface due to tin coating

Density: ~8.9–9.0 g/cm³

Tinned copper conductors are widely used in outdoor or marine environments where moisture, salt, and oxidation are common. The tin layer prevents the copper from oxidizing, maintaining stable conductivity over time.

The electrical resistivity is slightly higher than bare copper (~0.0178 Ω·mm²/m), but the trade-off is worthwhile for the superior corrosion resistance and long service life.

Advantages:

-

Excellent corrosion resistance in humid environments

-

Easy to solder and terminate

-

Long operational lifespan

Disadvantages:

-

Slightly higher material cost

-

Marginally higher resistance than bare copper

Typical Applications:

-

Outdoor solar PV cables

-

Marine energy systems

-

Battery harnesses and storage cables

2.5 Copper Alloy Conductors (High-Strength Types)

Material Name: Copper Alloy (e.g., CuMg, CuSn, CuCrZr)

Elemental Composition: Copper base with magnesium, tin, or chromium-zirconium

Abbreviation / Code: CuMg, CuSn, CuCrZr

Appearance: Reddish metallic tone

Density: ~8.7–8.9 g/cm³

Copper alloy conductors are developed to meet the needs of high-strength and high-temperature environments. Adding elements such as magnesium or chromium enhances tensile strength (up to 400 MPa) and fatigue resistance without drastically reducing conductivity.

Their resistivity ranges from 0.018 to 0.020 Ω·mm²/m, offering a balanced performance for demanding conditions such as EV fast charging or robotic automation systems.

Advantages:

-

Excellent strength and fatigue resistance

-

Stable conductivity under vibration and heat

-

High reliability and long service life

Disadvantages:

-

More expensive than standard copper

-

Limited availability in some markets

Typical Applications:

-

EV charging cables

-

Industrial robots and automation harnesses

-

Energy storage systems under mechanical stress

3. Comparative Summary Table

| Conductor Type | Density (g/cm³) | Resistivity (Ω·mm²/m) | Strength | Corrosion Resistance | Cost | Key Advantages | Typical Applications |

|---|---|---|---|---|---|---|---|

| Copper (Cu) | 8.96 | 0.0172 | High | Excellent | High | Best conductivity | PV, EV, storage |

| Aluminum (Al) | 2.70 | 0.0282 | Low | Good | Low | Lightweight | Power, transmission |

| CCA | 3.8 | 0.026 | Medium | Good | Medium | Balanced performance | EV, storage |

| Tinned Copper | 8.9 | 0.0178 | High | Excellent | High | Anti-corrosion | Outdoor, marine |

| Cu-Alloy | 8.8 | 0.018–0.020 | Very High | Excellent | High | Strength + conductivity | EV, robotics |

4. Key Factors in Choosing a Conductor for New Energy Cables

When selecting a conductor for new energy cables, engineers and manufacturers must balance several technical and economic factors:

-

Electrical Efficiency: Lower resistivity means less energy loss and heat generation.

-

Mechanical Performance: Strength, flexibility, and fatigue resistance affect installation and long-term reliability.

-

Environmental Conditions: Exposure to moisture, salt, UV radiation, or vibration determines whether special coatings (like tin or alloying) are needed.

-

Weight Considerations: In electric vehicles and portable systems, lightweight materials improve energy efficiency.

-

Cost and Availability: Material price can significantly influence total project cost.

-

Compliance Standards: Conductor materials must meet international standards such as IEC 60228, UL 758, UL 4703, or TÜV EN 50618 depending on the cable’s use case.

5. Conclusion

Each conductor material offers unique advantages in new energy cable applications:

-

Copper remains the benchmark for superior conductivity and mechanical reliability.

-

Aluminum is preferred where weight and cost savings are priorities.

-

CCA provides a practical middle ground between copper’s performance and aluminum’s economy.

-

Tinned copper excels in harsh, humid, or outdoor environments.

-

Copper alloys are ideal for high-strength, vibration-prone, or high-temperature applications.

Choosing the right conductor type depends on application demands, environmental exposure, and budget constraints. By understanding the differences in composition, density, electrical resistivity, and performance, WinpowerCable can design efficient, durable, and cost-effective new energy cable systems that meet the challenges of tomorrow’s sustainable power networks.

Post time: Nov-11-2025